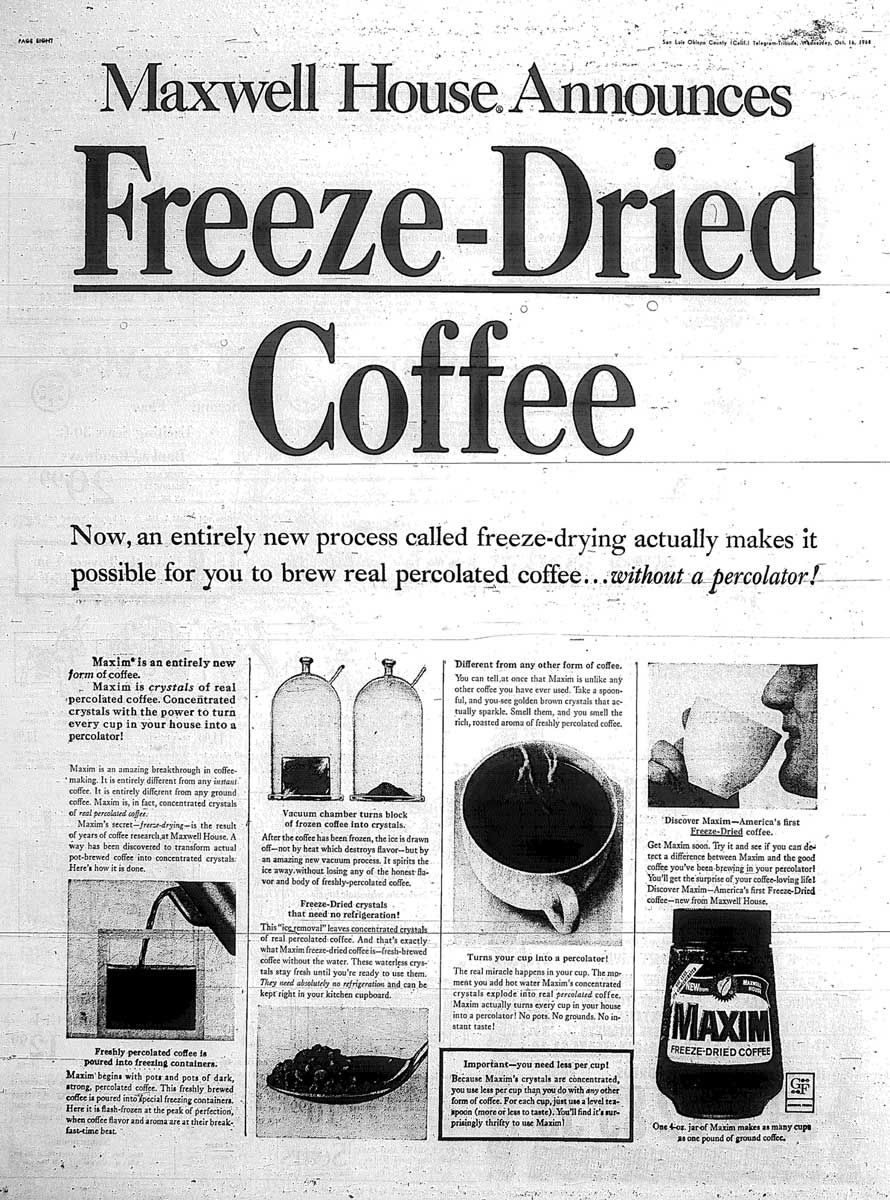

Freeze Dried Coffee Process

Instant coffee is commercially prepared by either freeze drying or spray drying after which it can be rehydrated.

Freeze dried coffee process. This is in contrast to dehydration by most conventional methods that evaporate water using heat. It is hard to get the strength of the coffee incorrect since coffee drinkers can simply add more. By the time the coffee droplets land they have dried into a powder the second method is freeze drying where the. Coffee is the most common freeze dried liquid.

The result is frozen below zero and the freeze drying machine creates a vacuum to lower the pressure. Chunks or slices of shrimp crab lobster beef and chicken can be freeze dried. On this process the pressure in the equipment used is also being lowered. All that is needed is a cup and hot water.

Instant coffee starts off as well coffee. Our head of coffee umeko brews the freshly roasted coffee using a process specially designed for sudden. But how does it get from freshly brewed cuppa to powdery flake. A hint of heat is applied in the primary drying phase.

Once model parameters are known the dynamics of the process can be described by the simplified one dimensional model of velardi and barresi 4. The coffee ice is broken into granules. The coffee extract is chilled at about 20 degrees f into a coffee slushie. Freeze drying coffee involves a few steps.

First lowering the temperature to approximately 40 o f 40 o c. Obtaining freeze dried coffee is an amazing process. It is composed by the energy balance for the frozen product and the mass balance for the dried layer figure 2 shows an example of the results that can be obtained when simulating the freeze drying of a coffee extract 25 by weight of coffee processed. That being done the frozen water s sublimation will occur.

Instant coffee also called soluble coffee coffee crystals and coffee powder is a beverage derived from brewed coffee beans that enables people to quickly prepare hot coffee by adding hot water or milk to the powder or crystals and stirring. In the first liquid coffee is sprayed in a fine mist through very hot very dry air. Roasting the purpose of roasting is to develop aroma color and soluble solids of the. Liquids thin portions of meat and small fruits and vegetables can be freezedried easily.

Because of the low temperature used in processing the quality of the rehydrated product is excellent. The brewed coffee is frozen at subzero temperatures. Therein lies the science there are actually two methods for making instant coffee. In cafesca we possess the most recent technology.

By making the temperature this low the water content will be frozen. It is ready as soon as the crystals of coffee dissolve in the water. Also freeze dried coffee does not require any equipment such as a coffee maker. Freeze dried coffee is ready faster than brewed coffee.

The coffee slushie is then further chilled on a belt drum or tray to 40 degrees f until it forms slabs of coffee ice. Never going above zero. First the coffee is cooked down into an extract. We maintain strict control and monitoring of all stages of the process guaranteeing the quality of our production.

The process of making freeze dried coffee includes various steps.