Frangible Tank Roof Design

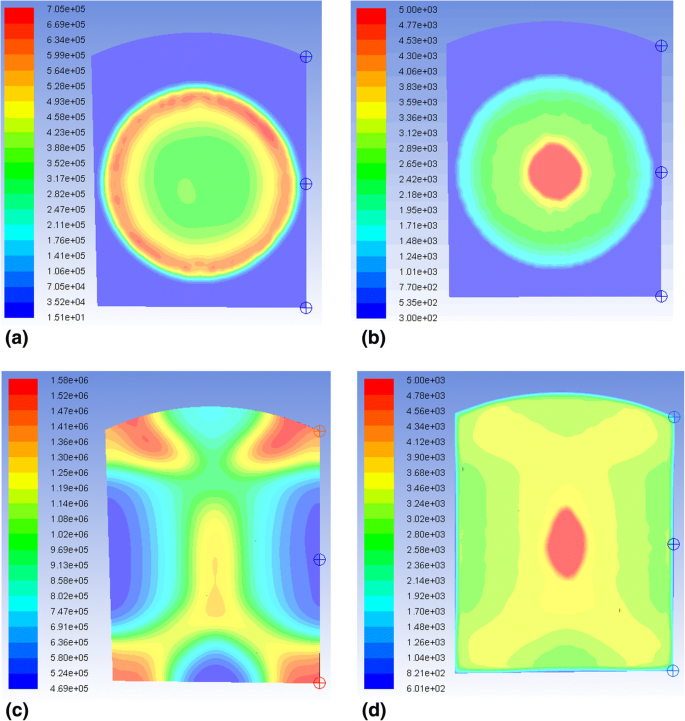

Describes research that evaluates the ability of the present api 650 tank design criteria to ensure the desired frangible joint behavior.

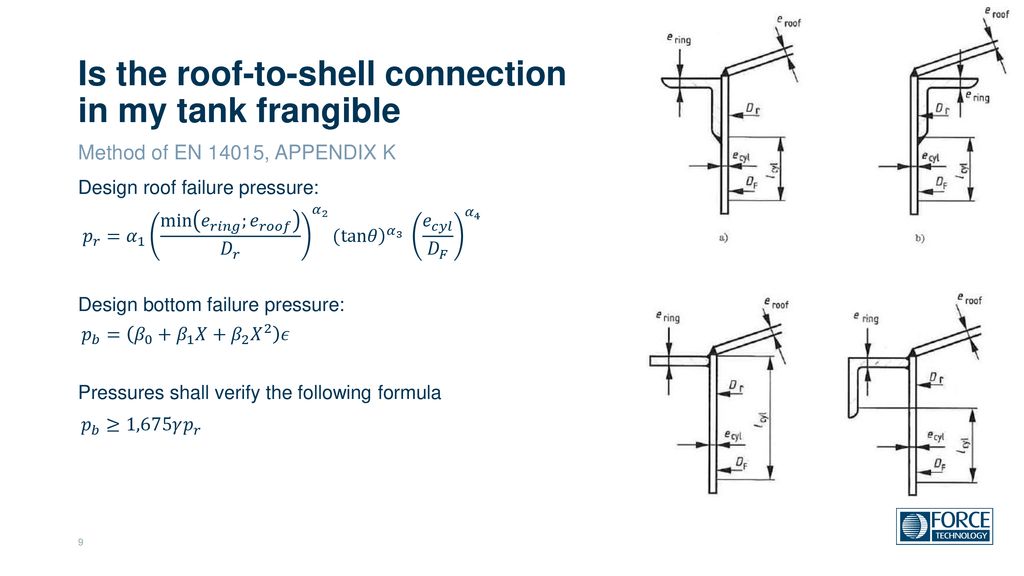

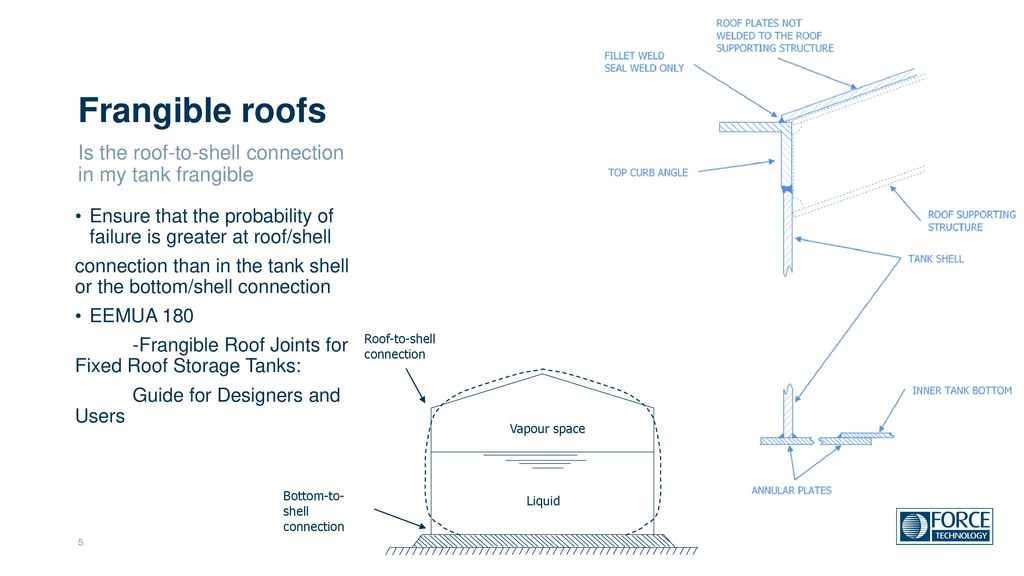

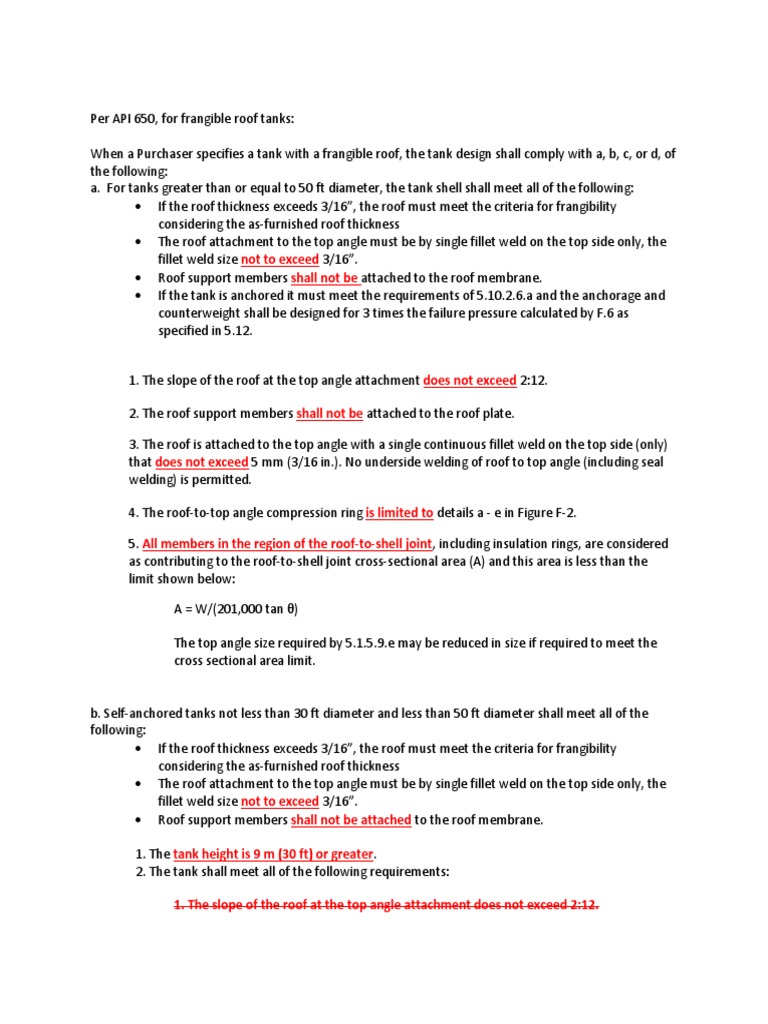

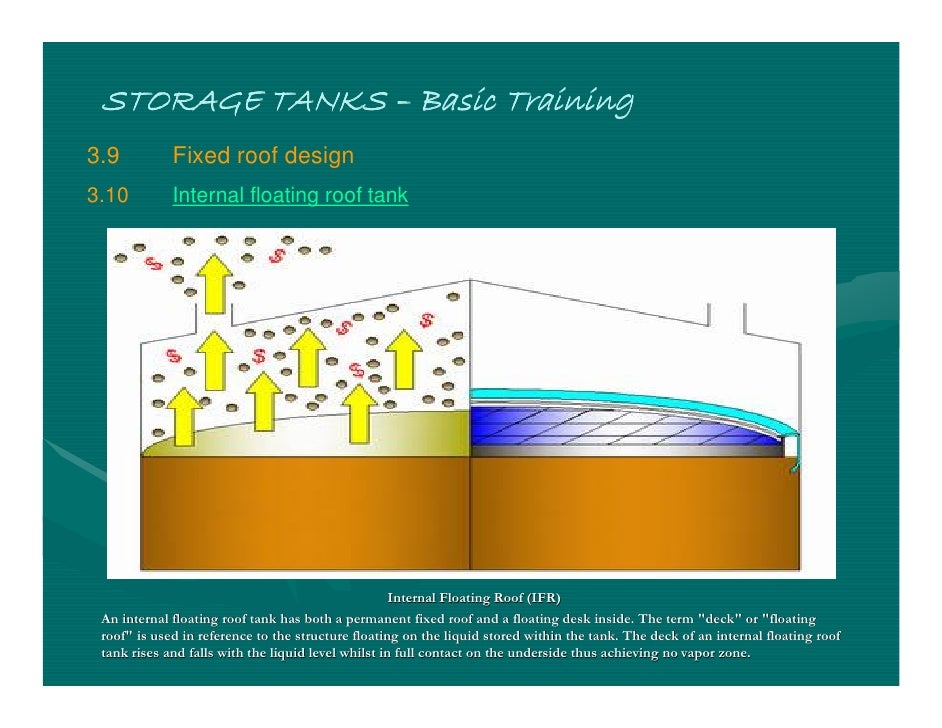

Frangible tank roof design. This standard provides for the design of a frangible roof joint but in 1978 the standard was amended to limit applicability of the frangible roof design to tanks having a diameter of fifty feet 15 2m or more. In particular i asked about the requirement if 5 10 2 6 d which says for anchored tanks of any diameter the tank shall meet the requirements of 5 10 2 6 a and the anchorage and counterweight shall be designed for 3 times the failure pressure calculated by f 6 as specified in 5 12. At the api committee meeting in november i brought up the subject of the frangible roof design requirements. This failure is intended to vent the tank and contain any remaining fluid.

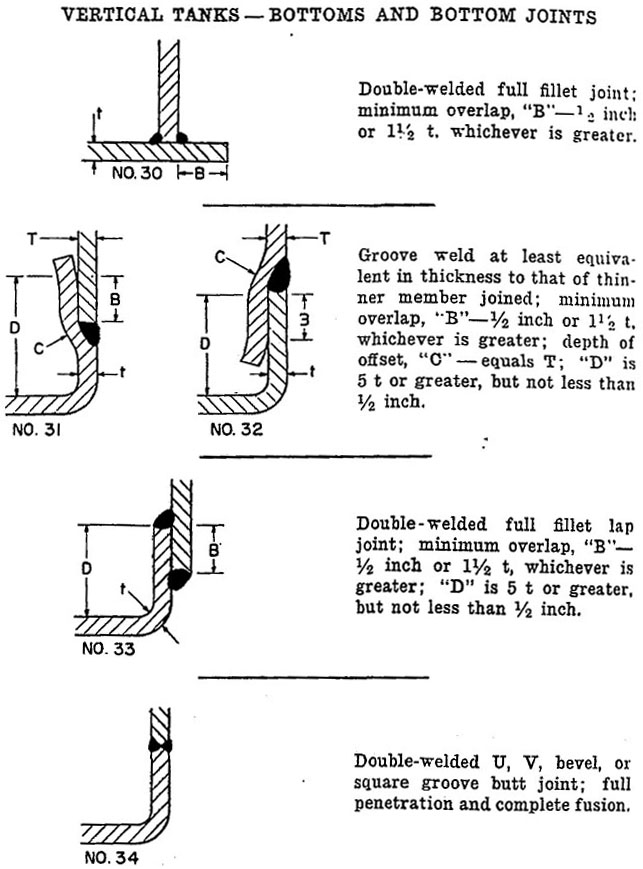

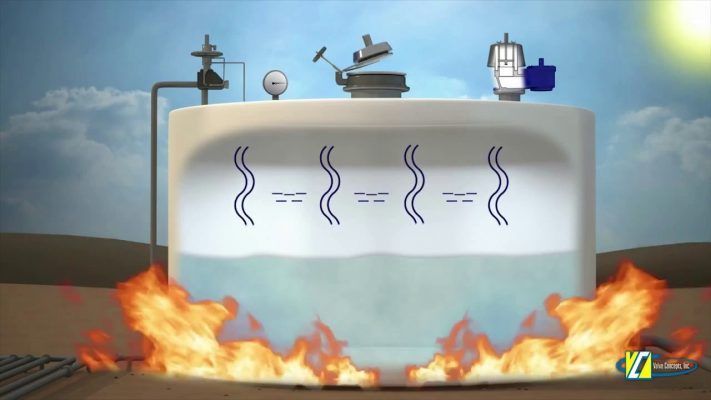

Api 650 gives rules for the design of frangible roof joints in fluid storage tanks. That is of course if the tanks are built according to the rules for frangible roofs. The api 650. In such tanks the roof to shell joint is intended to fail in the event of overpressurization venting the tank and containing any remaining fluid.

This video documents the research and testing on frangible joint storage tanks performed at kansas state university and thunderhead engineering. This paper presents the results of an investigation into the frangible joint behavior of tanks designed to api 650 rules. On fixed roof tanks where the roof shell attachment is constructed according to api standard 650 1 the roof to shell joint may be considered frangible so that excessive internal pressure may cause it to fail before failure occurs in either the tank shell joints or in the shell to bottom joint. 1 evaluation of the area inequality as a method to predict the buckling response of the compression ring 2 effect of roof slope tank diameter and weld size on the frangible joint and 3 effect of the relative strength.

In the event of over pressurization the frangible roof to shell joint is designed to fail before the tank shell or the shell to bottom joint. However in the context of tanks the word has a specific meaning and is defined in the main tank construction standards bsen 14015 and api650. The american petroleum institute api has developed a standard for the design and construction of welded steel storage tanks. In fact the frangible roof design fulfills the venting requirements due to deflagrations inside tanks for most tank sizes greater than about 35 feet in diameter.