Double Wall Storage Tank Leak Detection

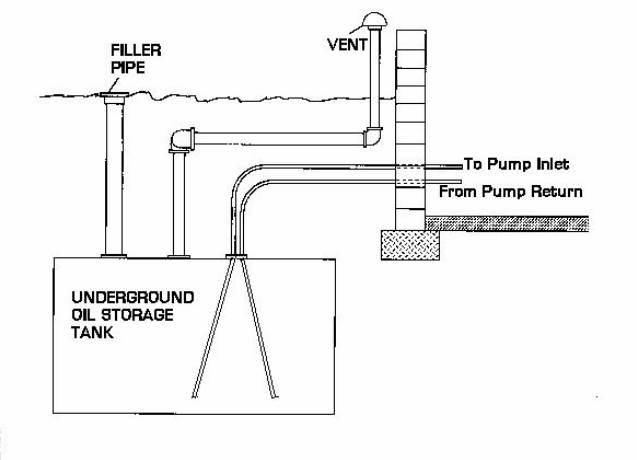

The product level and temperature in a tank are measured and recorded by a computer this saves labor and time.

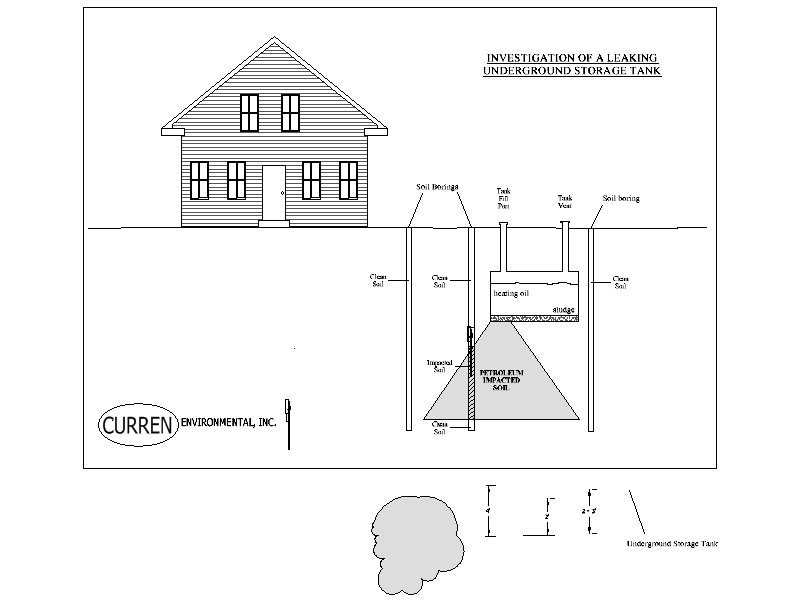

Double wall storage tank leak detection. If you are new to online filing please see online filing forms before beginning. Methods of leak detection for underground storage tanks. Owner operators of underground storage tank ust systems in massachusetts are required to. The barrier holds the leak between the tank and the barrier so that the leak is detected.

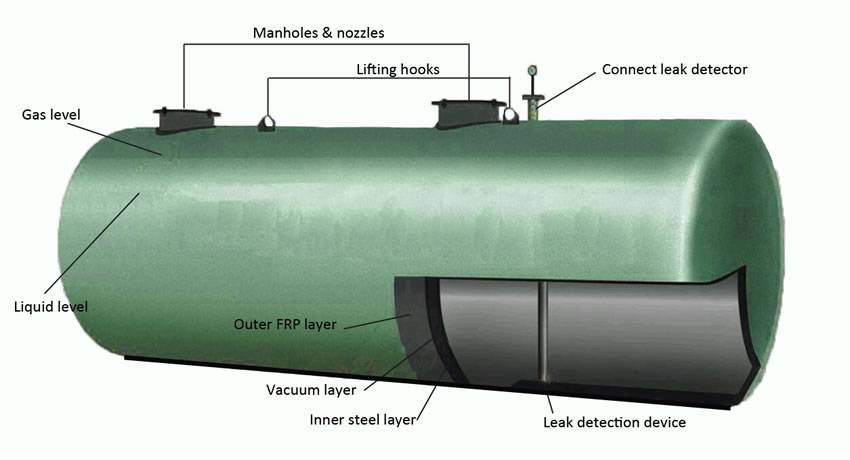

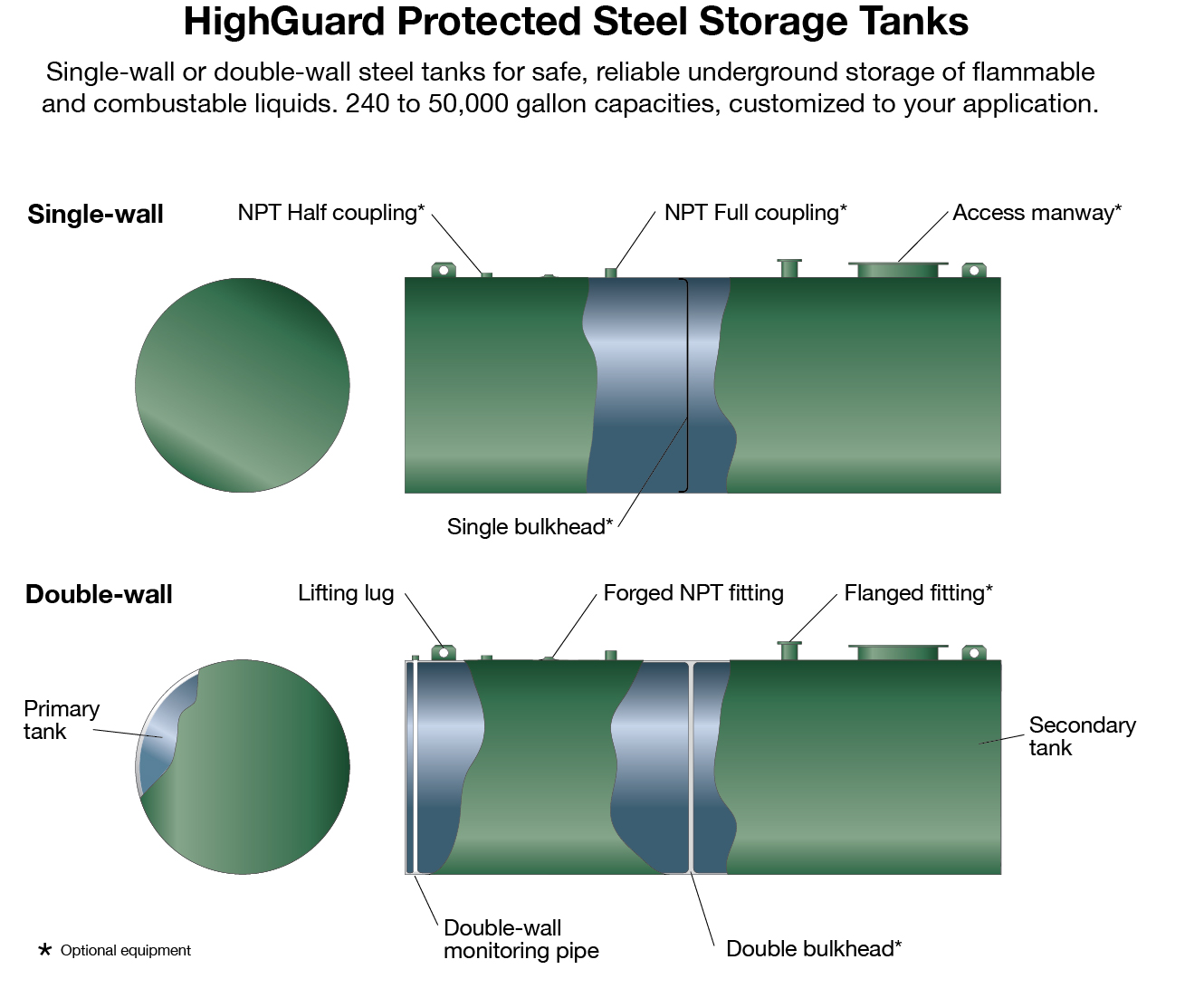

System that monitors pressure of a liquid filling the interstitial space of a double wall system. Suitable for both indoor and outdoor double wall tank applications. Horizontal cylinder vertical or rectangular tanks wit or without fuel soap tested leak test solution applied to surfaces fittings welds etc. High accuracy level sensors with proprietary software allow continuous real time leak exposure detection and high accuracy for custody transfer and inventory management.

The system alarms on any leak. To check for leaks. Once a leak is detected fuel can be removed from the tank before any product enters the environment. Leak detection sensors for interstitial monitoring in double wall tanks and brine reservoirs non discriminating interstitial sensor for double wall fiberglass tanks the non discriminating interstitial sensor for double wall fiberglass tanks detects the presence of liquid in the interstitial space of the tank.

Tank monitoring ronan s x76ctm continuous tank monitoring system provides state of the art automatic tank supervision for hydrocarbon fuels and other liquids stored in under. Southern tank has been manufacturing standard double wall tanks see charts for horizontal tanks and vertical tanks for years. Atg systems operating in continuous in tank leak detection test mode are covered under continuous in tank leak detection. Section 3 0 covers leak testing of single walled and double walled aboveground storage tanks test pressures dependent on type of tank i e.

Customizing double wall tanks to your specific needs. Items such as fill systems with overfill and spill protection emergency and working vents gauges alarms pumps leak detection devices and so on can be provided. Interstitial monitoring requires secondary containment like a double wall tank or double wall piping which provides a barrier between the tank or piping system and the environment. Employ at least one massdep certified class a b and c operator.

Interstitial leak detection and other accessories available for double wall tanks designed with a nema 4x enclosure.